A drug’s effectiveness depends on how well it is absorbed into a patient’s bloodstream. Nayan Solanki, a doctoral student in the College of Pharmacy and Health Sciences, has devoted his research to developing a variety of techniques to improve drug water solubility and more efficient delivery of drugs to the body.

Last November, Nayan received a Graduate Student Award from the International Pharmaceutical Excipients Council of the Americas (IPEC) Foundation for his research on how inactive ingredients, known as excipients, can improve water solubility and absorption of drugs, thus enhancing the drug’s performance. As part of the award, Nayan received a scholarship of $1,500 from IPEC and was honored at the American Association of Pharmaceutical Scientists annual meeting last November.

Since arriving at St. John’s, Nayan has worked in the Serajuddin Research Lab under the mentorship of Abu Serajuddin '82Ph.D., Professor of Industrial Pharmacy. In addition to improving solubility, Dr. Serajuddin’s work focuses on systems, such as nanoparticles, microemulsion, and 3D printing.

Nayan uses pharmaceutical excipients such as polymers (materials made of long and repeating chains of molecules) to improve the dissolution rate of poorly water-soluble drugs by using a process known as hot-melt extrusion (HME), which makes drugs absorb faster into the body. HME is a century-old technique widely used in the plastics industry to process thermoplastic and rubber into the end products. This technique has been adapted by the pharmaceutical industry in the formulation of solid dispersions. Drugs from solid dispersions can dissolve faster, absorb quicker, and provide better patient benefits.

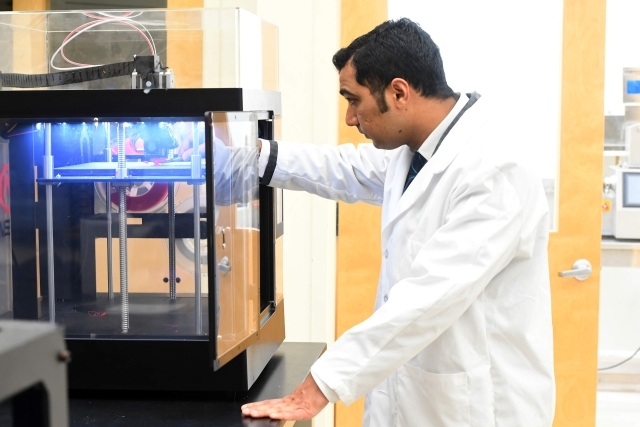

Another important facet of Nayan’s research is the use of 3D printing to create a tablet that delivers the doses according to a patient’s need. “Tablets are not ‘one size fits all,’” he noted. Tablets come at certain fixed doses (e.g., 25 or 50 mg), but because every patient’s metabolism and genetic factors are unique, either of these doses may be too much or too little. With 3D printing technology, he produced a tablet customized for a specific patient. “3D printing has unlimited potential,” Nayan stressed. Many different drugs can also be printed into a single tablet for patient convenience.

Nayan wanted to become a doctor but found his interest in innovating new medicines. Originally from India, he opted to continue his studies in the United States because more than two-thirds of new medicines in the world are discovered and developed here. One reason he chose St. John’s was its proximity to the many pharmaceutical companies within the tristate area.

“St. John’s University has state-of-the-art research facilities,” he said. “We receive great guidance and support from our colleagues and the administration, as well as generous financial support from the College of Pharmacy and Health Sciences.”

Nayan recently successfully defended his thesis and now seeks employment opportunities in the pharmaceutical industry. He hopes to find a position that allows him to continue the same research path that defined his graduate studies: finding better delivery systems for drugs that have already proven extremely beneficial. “We have better drugs, but we need better therapies, and that is where I believe I can be most useful.”